EDM 24NII automatic sliding door operator is the perfect choice for commercial sliding pedestrian doors.

A very high quality, ultra-reliable automatic sliding door operator system, working continuoulsy for many years and employed in all manner of applications world wide. EDM NII Series will provide you with assured long term service guaranteed.

CE, EN16005 compliant and UL approved. EDM NII Series is designed specifically to meet the highest demands in world safety.

Utilising our advanced Microprocessor control unit together with a Brushless motor, EDM NII Series is a high quality, automatic sliding door solution for easy open and close operation, offering a wide range of parameter adjustments and with a host of features and benefits.

> High quality and reliable sliding door solution

> Safe & long term operation guaranteed

> Quick installation and set up

> Memorised ‘one time’ teaching stroke

> Easily accessible inputs

> LED Digital control display

> Wide parameter adjustment

> Energy saving (partial open) function

> Emergency Stop

> Ratchet (flip flop) function

> Battery open or close

> Electromagnetic lock (fail safe or fail secure) option

> CE, EN16005 compliant and UL approved

Design – Its compact size and functional housing design will compliment any installation project. Designed to automate door panels of either single of bi-parting configuration.

Quality – Utilising our advanced microprocessor control unit with a brushless motor, we achieve near silent and smooth motion. Highly reliable, using only quality electronic parts, EDM NII Series automatic sliding door operators adapt effortlessly to varied door widths and weight capacities.

Installation – With all parts installed directly from the front, any component can be moved during or after installation. Parts can also be added or replaced with ease, greatly reducing time spent at site. Adjustment can be achieved simply making MICOM sliding door operators quick to install and setup.

Wiring – Available with a quick plug-in wiring hub ‘SMB’ interface board, we can offers a faster means of accessory connection, battery and sensor monitoring. Communication of all accessory and safety signals are combined with battery input and lock control. Working in parallel, these signals are controlled via our Selector Switch for greater ease of operation by the end user. All signals and sensor accessories are monitored, complaint with EU Norm EN16005.

EDM NII can also be used without ‘SMB’ interface board and can accept all current sensors available in the world market today, with the use of our connection terminal provided as standard,

Set-up – Door stroke is memorised one-time during initial installation or for servicing requirements. There is no need for the operator to re-learn each time the main power is turned on.

Parameter Setting – A wide selection of operational parameters are available and can be adjusted to suit each installation with ease. Operational parameters can be adjusted to suit individual installations, through the easily accessible LED visual display found on EDM NII Control box face.

Compliance – Designed specifically to meet the highest demands of the world market, EDM NII Series are CE, EN16005 compliant and UL approved.

Delivery – EDM 24NII is available from Japan as a pre-assembled sliding door operator or as a component building KIT.

Suitability – Commercial Entrance or Main Door: For installation in Airports, Hotels, Hospitals, Shops and Stores, Liabries, Schools, Office Buildings and Factories

Introduction

EDM 24NII sliding door operator forms the basis to any door automation solution. Equipped with our trademark microprocessor control and powerful motor drive system, EDM 24NII adapts effortlessly to varied door widths and weight capacities.

Ease of Installation

- With modular plug-in parts installed directly from the front onto our base rail, any component can be moved during or after installation. Components can also be added or replaced with ease later, therefore time spent on installation or servicing is greatly reduced.

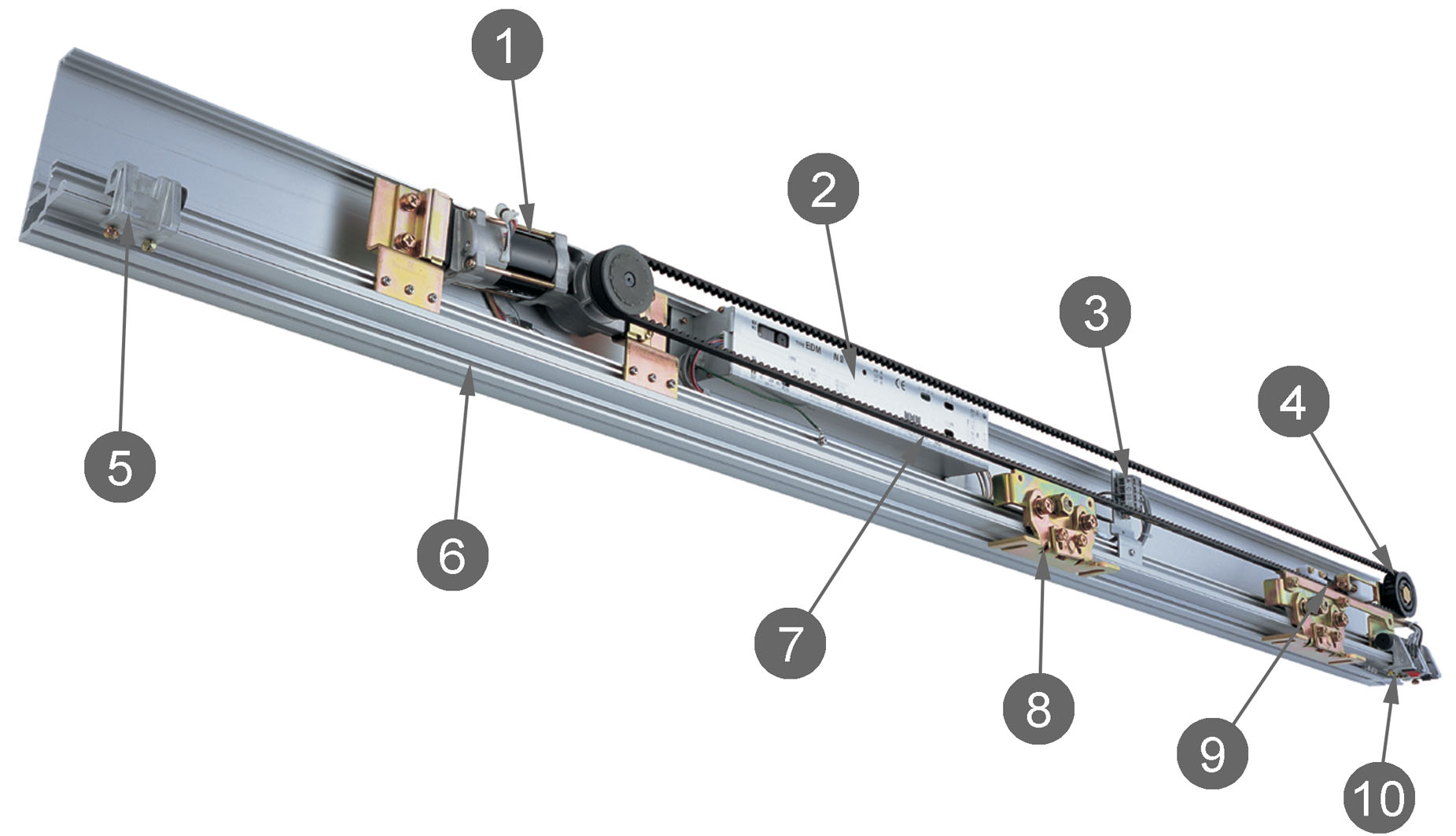

EDM 24NII Operator

- Motor with mount bracket and vibration proof rubber

- Control box assembly

- Terminal Input

- Idle pulley

- End stopper

- Rail

- Tooth belt

- Hanger roller bracket

- Belt tightening bracket

- Power switch

Full Door Control

- From the very first power on, initial door optimisation is automatic. Utilising the LED Digital input display provided as standard (without the need for a hand held PALM or expensive software) all standard parameters and extension applications can be adjusted easily. Access to operational history, cycle count and error analysis is possible. Door parameter data can be simply reset to default settings when required.

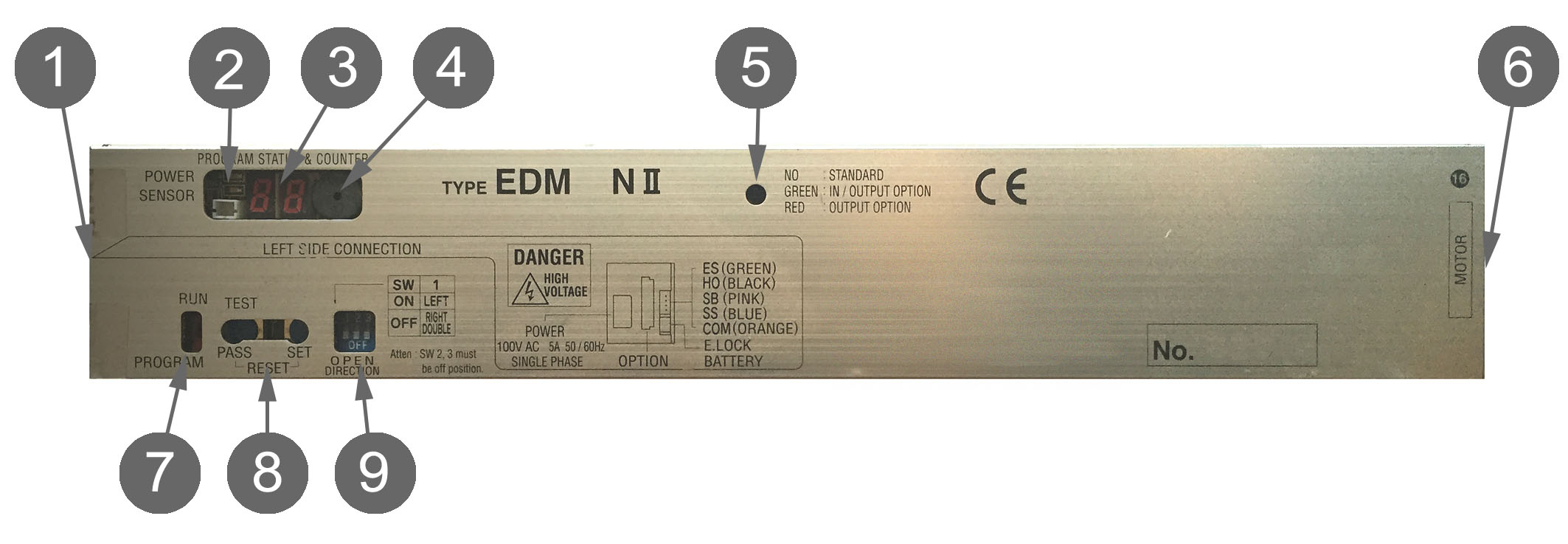

Control Panel & Adjustment

- Power and sensor harness input

- Power and activation LED

- 2 Digit LED display

- Buzzer

- Extension board LED (option)

- Motor harness input

- Programme / Run

- Test / Pass & Set (Reset)

- Right / Left opening

- SENSOR LED – Flashes Green when activation signal is received

- POWER LED – Red when power is on to operator

- PROGRAM STATUS & COUNTER LED – Visual display provided for operational setting and adjustment

- Buzzer – Audible indication of error status (optional)

- Exetension Board LED – Through this hole, it is possible to identify if an extension card has been fitted

- Progamme / Run Switch – Utilized to enter the programming mode

- TEST / PASS & SET – Programme Buttons. Provides stepped access to parameters, functions, applications and reset

- DIP Switch – Quickly adjustment of open direction between Right or Left

Summary

Control Box

- Function & Parameter Adjustment – Microprocessor technology provides exact door control, wide function input options and digital setting adjustment.

- Memory – Long term memory retention of operational parameters when mains power is off. Settings can be rewritten up to 1 billion times.

- Extended Functions (i.o) – Aside from standard function common to all other sliding door operators, when incorporating expansion (i.o) board, EDM NII Series offers many more door operation possibilities.

Standard Inputs

- Sensor / Activation Signal (SS)

- Threshold Protection (SB)

- Hold Open (HO)

- Emergency Stop (ES)

- Panic Open (PS)

- Ratchet Switch (RS) (Flip Flop)

- Partial Open (HS)

- Side Screen Safety (AS)

Function Summary

- Digital Input Programming

- Wide Operational Parameter Setting

- System Error Diagnosis

- Self-protection against Damage

- Flexible Partial Open (13%~98%)

- Press Open / Close Feature

- Special Operation Functions Incorporated

- Reversible Circuits (NC/NO)

Motor Gear

- Compact and powerful motor. High speed acceleration and deceleration is controlled.

MICOM enclosed hypoid brushless motor gear ensures safe and long term reliable operation for

enhanced operational cost efficiency.

- High Speed Motor Control (750mm/s)

- 120kg~240kg Load Capacity

- Compact High Precision Gear Box

- Near Silent Acceleration and braking

- Smooth and controlled operation

Monitoring & Safety – (SMB Option)

- SMB is a SENSOR & BATTERY MONITORING SYSTEM which offers compliance with EU Norm EN16005 across our range of EDM Series automatic sliding door operators. A modular system for enhanced automatic door safety. Simple to install, offering added protection and multi-functional features which include:

- Conforming to EN16005

- Individual Sensor Monitoring & Safety

- Battery Functions & Monitoring

- Key Function Selector Switch

- Individual Sensor Inputs & Wiring

- LED Indicator (Mode & Error)

- Emergency Open Input

- 24VAC Power Input (Isolated Transformer)

- Night Mode (Switch) Input

- Secure E-Lock Functions

SMB Features

- Signal Input Connection

- External Sensor Input

- Internal Sensor Input

- LED Monitoring Error & Battery Indicator

- DIP Switch – Sensor & Battery Monitoring On / Off

- E-Lock Timer

- Side Screen Input 1

- Side Screen Input 2

- Battery Pack

- Selector Switch Connection

- E-Lock Input / Output

- Battery Connector (Not shown)

Key Selector Switch

- A Rotary Key function selector switch is supplied together with SMB.

- SMB will not function without our selectors and it is therefore an integral part of our safety in design.

- Connected into the SMB hub, all signals are controlled for greater ease of operation.

- Specifically designed so selection can only be performed by an authorized personnel using secure key provided.

Rotary Key Selector

1. Closed / 2. Exit / 3. Automatic / 4. Hold Open (Emergency – Anti Panic Open Button – Option)

Electro-Mechanical Locking & Battery (Standard Anti-Panic Option)

- Battery – An Anti-panic Battery system is available in several formats providing emergency power in case of power failure such as Battery Open (BO) and Battery Close (BC), with Battery Monitoring System (BMS) is

available. - Electromagnetic Locking – EDM NII Electromagnetic locking ‘Fail Secure’ (LK1) or ‘Fail Safe’ (LK2) options are available and can be combined with our battery systems to meet safety and security requirements world wide.

Delivery

EDM 24NII Series – Available from Japan in formats as follows:

- ‘COMPLETE OPERATOR’ consisting of: Base Rail, Cover, Control Box, Motor Gear Box, End Covers, Sensor Harness, Wiring Terminal, Tooth Belt, Belt Bracket Link Assembly, Belt Connection Single & Double Door, Idle Pulley, Hanger Roller Brackets x4 and Stopper x2

(COMPLETE OPERATOR – Standard Rail Length: Single Leaf – 2000mm, Double leaf – 5000mm) - ‘FULL KIT’ – (Without Rail & Cover) consisting of: Control Box, Motor Gear Box, Sensor Harness, Wiring Terminal, Tooth Belt (7M), Belt Bracket Link Assembly, Belt Connection Single & Double Door, Idle Pulley Assembly.

- RAIL & COVER – (Material Only) – Standard Length: 2000mm – 5000mm Available

Accessories

EDM NII together with SMB when used as a complete operator is designed for use with a new range of sensors such as BEA IXIO-S & Optex 0A-Axis-T.

EDM NII when used without SMB can also accept all current sensors available in the world market today, such as BEA Eagle & Optex OA-203C together with threshold safety beam protection.

EDM NII when used without SMB can also accept all current sensors available in the world market today, such as BEA Eagle & Optex OA-203C together with threshold safety beam protection.

| Model | EDM 24NII-A-S | EDM 24NII-A-D | |

| Application | Single Slide | Double Slide | |

| Applicable door (max) | Dimensions | DW1219xDH2134mm | |

| Weight (kg) | 120 | 120x2 | |

| Opening / Closing Speed | 100~750mm/s 10 step adjustable | ||

| Hold Open Time | 0~60 Sec. 16step adjustable | ||

| Power Supply / Consumption | 100V AC +/- 10V 50/60Hz | 150 Watt (max) | ||

| Rated Operation | 1 million opening and closing cycle test completed | ||

| Door Open / Close Force | High Speed 216N (22kg) Low Speed 176N (18kg) 10 Step Adjustable |

||

| Motor Power | 40 Watt | ||

| Motor Type | Brushless molded DC motor | ||

| Reduction Gear | Enclosed hypoid gear system | ||

| Control System | Microprocessor Control | ||

| Dielectric Strength | AC1000V for one minute | ||

| Operating Environment | Ambient temperature -20C ~ +50C (no condensation or icing) Ambient humidity 30% ~ 85% RH (no hazardous materials must be present in the atmosphere) |

||